Maintenance and Support

You May Also Be Interested In

1010G Forwarder

- Load capacity 11 tn

- FT4-engine John Deere 4045

- Several accessories options

- IBC and long rear bogie options

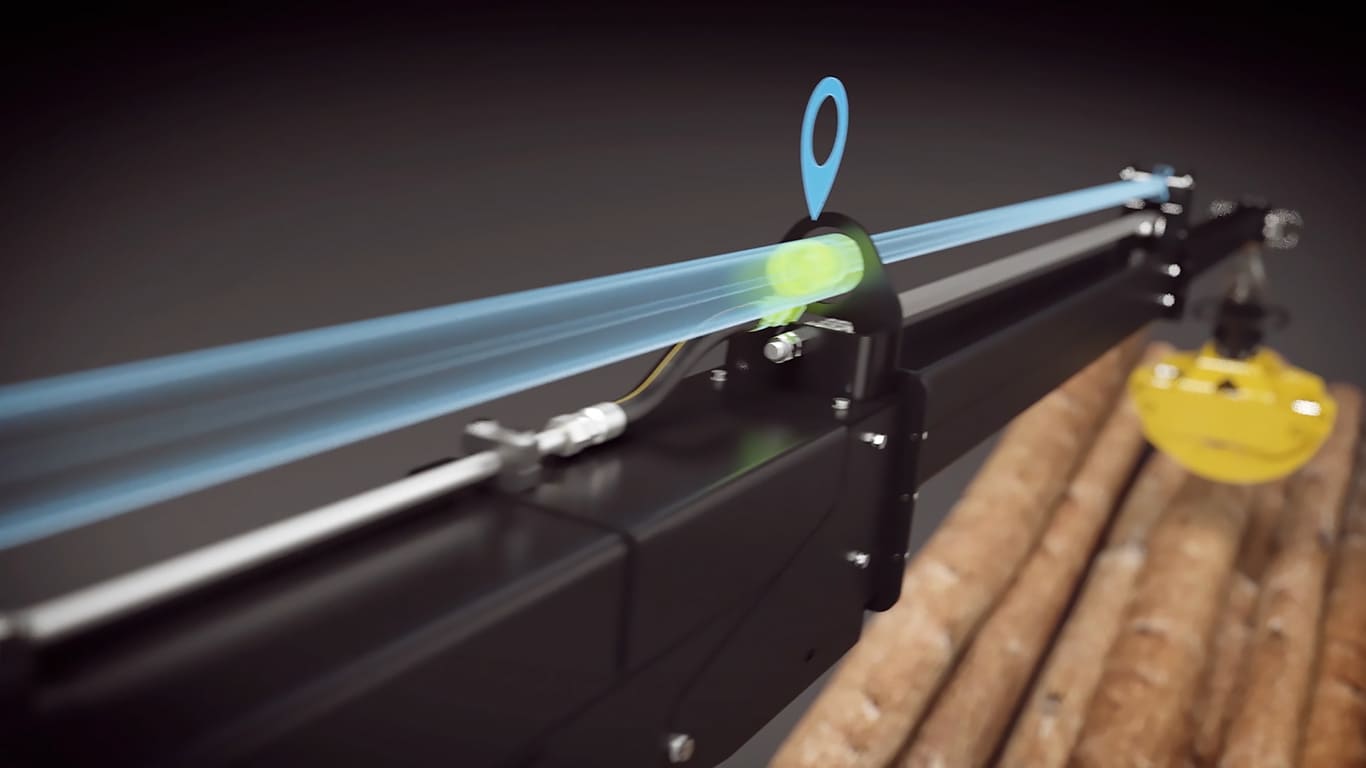

Exact location of each log

The data between the machines are updated through a cloud service, and all the operators working at the same work site can see all the tree species and assortments with the driving routes right down to the individual logs.

Timber in good order

Sorters make it easy to sort the timber in the forwarder’s load area. Sorters are easy to use. The tiltable sorters can be quickly tilted with the grapple. The sorters stand about 20 cm high when vertical and about 10 cm when tilted.

With TimberMatic Maps, the different assortments can be highlighted with different colors by marking them as favourites. This together with the sorters, helps to separate the assortments and to build the load already sorted which speeds up the unloading considerably.

Specifications

Collapse all

Expand all

1010G

| Engine | John Deere 4045, 4,5 l

|

| Tractive force |

|

| Hydraulics | Pump volume 140 cm3 |

| Boom |

|

| Load space |

|

| Load capacity | 11 tons |

| Control system | TimberMatic |

| Cabin | Fixed or rotating and levelling |

| Length |

|

| Tires |

|

| Min. weight with R & L cabin |

|

| Min. width with 700-series tires |

|

| Turning angle | +44o |

Product program

Product Program wheeled cut-to-length

Powerful XE-extension

The XE-extension is a single extension and jib boom with external hosing for CF5, CF7 and CF7S 8,5 m booms of the small and mid-size forwarders.

Electrical cylinder end damping

The Intelligent Boom Control features electrical end damping for all the main boom movement directions. The system dampens the cylinder end movements softly and stops strong blow-like loads in the end positions.

Features

Collapse All

Expand All

Intelligent Boom Control IBC

The precision and power of the G-Series forwarders’ boom control is unprecedented. The controllers, simplified CAN busses and streamlined electrical systems bring more power, speed and precision control to the boom. The updates decrease malfunction sensitivity and accelerate troubleshooting. The number of fuses has been reduced thanks to controllers that recognize overcurrent situations and cut the feed when necessary to protect the equipment.

IBC is available as an option for CF5 boom. The boom becomes more accurate and easy to operate: the operator controls the boom tip directly instead of controlling independent boom joint movements. The system also considerably reduces the number of tuning parameters needed and increases durability of boom structures and hydraulic cylinders.

The system has predefined limit values and it adjusts boom operations within these limits according to need. IBC system also has a separate, preprogrammed option for unloading, where the strong jib and main boom movements are used more.

In the latest 2.0 version of intelligent boom control, the precision of the grapple control has been improved, especially in long reaches. The software uses information about the grapple position, and the speed of the rotation in long reaches matches that of short reaches.

Electrical cylinder end damping

The IBC system also features electrical end damping for all the main boom movement directions. The system dampens the cylinder end movements softly and stops strong blow-like loads in the end positions which makes driving smoother and also improves the durability of the boom.

Operator adjustments

Operators can adjust the overall speed of the IBC system according to their needs. They can also adjust the speed between various boom parts or change it by using the extension boom manually during operation. The system is switched on and off with the press of a button.

Adaptive driveline control

Adaptive driveline control is a unique standard feature in G-Series forest machines. This control system improves the machines’ drivability and productivity. The operator selects the desired driving mode (Eco, Normal, Power) for the operating conditions, and the system automatically adjusts the engine’s RPMs to correspond with the engine load and keeps the driving speed steady also during high loads.

The driveline control ensures that the diesel engine runs smoothly and uses the available maximum tractive force efficiently during high-load situations. Also the response of the drive pedal and frame steering have been improved with smart electronic filtering.

XI and XE jib booms

XI jib boom with hidden hoses

There are no holes, brackets or other accessories at the front of the jib boom which would weaken the boom or would be prone to impact damage. Hoses and cables are covered by the boom structure and the hose routing between the main and jib boom and inside the extension pack have been redesigned.

Powerful XE jib boom

The XE-extension is a single extension and jib boom with external hosing for CF5, CF7 and CF7S 8,5 m booms. The design is simple and durable. It is easy to control due to good geometry, and visibility to the boom tip is very good with a boom light under the extension. Thanks to the outstanding extension pulling force, productivity is improved.

Well protected hose routing

The jib booms' Y-link hose routings are well protected and the hoses last long due to better routing. There are no external hose loops so the booms are easier to guide between trees in thinning and it is also easier to move the grapple between the bunks to the load space.

Wider load space

The manual type of VLS load space is available for 26,5 axles and with fixed headboard. The load area is 4,1 - 4,4 m2 and machine's width 2820 - 3040 mm.

Rear extension

The 600 mm rear extension is ideal for 2x3 m stacks. Bunk positions for 2x2,5 m stacks are offered as well. The rear extension is available for 26,5 axles with 4,0 m2 load space and the longest, 5200 mm rear frame option.

Big approach angle

With its 11-ton load capacity, light rear frame, big approach angle and powerful FT4 engine combined with the optional 26.5” tires, long rear bogie and IBC, the 1010G is a very versatile forwarder for thinning. Driving over ditches is very smooth, servicing is easy, and the engine is Stage V-ready.

Design for easy service

The 1010G forwarder has been designed by Designworks, a BMW Group company. Special attention has been paid to ease of service: a large panel on the right side of the engine hood can be opened and the upper part can be tilted forward. The fuel tank has been moved to the front and a hydraulic module has been added to the freed space behind the cabin. The hydraulic components in this module are easy to reach for servicing.

Low ground pressure bogie axle

A long-bogie version of the 1010G forwarder is available for logging on soft terrain. The distance between the front and rear wheel hubs in the rear bogie is 390 mm longer than in the standard model. The power train and turning radius are the same as with the standard portal bogie-equipped machine. The long bogie brings stability when navigating over obstacles. The lower ground pressure of the rear frame makes the machine an excellent choice for logging in soft terrain and enables bigger loads with the same ground pressure.

Control systems and automation

The TimberMatic control system and user interface on G-Series forwarders have been developed and improved to maintain the forest machine’s operational reliability. The TimberMatic features a configurable user interface, cruise control and inclination display. The software enables Remote Display Access (RDA) via the Internet (either MTG or other modem). RDA enables faster troubleshooting by servicing people and thus improves the machine’s uptime.

Forwarders have three modules: for the cabin, the front frame and the rear frame. TimberMatic’s troubleshooting diagnostics are detailed and illustrative. The CAN bus increases reliability of the electrical system: simple, fewer connections, a dedicated bus for the engine and the base machine.

TimberMatic Maps is standard in all new John Deere forest machines. Based on the real time data from TimberMatic Maps to TimberManager, distributed through a cloud service, the contractor can follow up forest machine’s production and remaining work on the site and plan the operations further.

FT4-engine

John Deere Final Tier 4 engines meet the required emissions regulations while also bringing more power and torque. The John Deere 4045 PowerTech Plus, 4,5 liter 4-cylinder engine’s output is 131 kW. The engine is also Stage V-ready.

Especially the low rpm ranges have much torque. The John Deere FT4 engine has the most torque in its class and a wide rpm range. The engine’s rpm remain steady during big and rapid changes in the load. The better coupling of the powerful diesel engine with the power train results in improved tractive force and excellent manoeuvrability in the forest. The FT4 engine and the entire fuel line can use 20% biodiesel.

Features

Collapse All

Expand All

Intelligent Boom Control IBC

The precision and power of the G-Series forwarders’ boom control is unprecedented. New controllers, simplified CAN busses and streamlined electrical systems bring more power, speed and precision control to the boom. The updates decrease malfunction sensitivity and accelerate troubleshooting. The number of fuses has been reduced thanks to controllers that recognize overcurrent situations and cut the feed when necessary to protect the equipment.

IBC is available as an option for CF5 boom. The boom becomes more accurate and easy to operate: the operator controls the boom tip directly instead of controlling independent boom joint movements. The system also considerably reduces the number of tuning parameters needed and increases durability of boom structures and hydraulic cylinders.

The system has predefined limit values and it adjusts boom operations within these limits according to need. IBC system also has a separate, preprogrammed option for unloading, where the strong jib and main boom movements are used more.

In the latest 2.0 version of intelligent boom control, the precision of the grapple control has been improved, especially in long reaches. The software uses information about the grapple position, and the speed of the rotation in long reaches matches that of short reaches.

Electrical cylinder end damping

The IBC system also features electrical end damping for all the main boom movement directions. The system dampens the cylinder end movements softly and stops strong blow-like loads in the end positions which makes driving smoother and also improves the durability of the boom.

Operator adjustments

Operators can adjust the overall speed of the IBC system according to their needs. They can also adjust the speed between various boom parts or change it by using the extension boom manually during operation. The system is switched on and off with the press of a button.

Adaptive driveline control

Adaptive driveline control is a unique standard feature in G-Series mid-size forwarders forest machines. This control system improves the machines’ drivability and productivity. The operator selects the desired driving mode (Eco, Normal, Power) for the operating conditions, and the system automatically adjusts the engine’s RPMs to correspond with the engine load and keeps the driving speed steady also during high loads. The driveline control ensures that the diesel engine runs smoothly and uses the available maximum tractive force efficiently during high-load situations. Also the response of the drive pedal and frame steering have been improved with smart electronic filtering.

XI jib boom

There are no holes, brackets or other accessories at the front of the jib boom which would weaken the boom or would be prone to impact damage. Hoses and cables are covered by the boom structure and the hose routing between the main and jib boom and inside the extension pack have been redesigned.

Wider load space

The new load space is a manual type of VLS and available for 26,5 axles and with fixed headboard. The load area is 4,1 - 4,4 m2 and machine's width 2820 - 3040 mm.

Rear extension

The 600 mm rear extension is ideal for 2x3 m stacks. New bunk positions for 2x2,5 m stacks will be offered as well. The rear extension is available for 26,5 axles with 4,0 m2 load space and the longest, 5200 mm rear frame option.

Big approach angle

With its 11-ton load capacity, light rear frame, big approach angle and powerful FT4 engine combined with the optional 26.5” tires, long rear bogie and IBC, the 1010G is a very versatile forwarder for thinning. Driving over ditches is very smooth, servicing is easy, and the engine is Stage V-ready.

Design for easy service

The 1010G forwarder has been designed by Designworks, a BMW Group company. Special attention has been paid to ease of service: a large panel on the right side of the engine hood can be opened and the upper part can be tilted forward. The fuel tank has been moved to the front and a hydraulic module has been added to the freed space behind the cabin. The hydraulic components in this module are easy to reach for servicing.

Low ground pressure bogie axle

A long-bogie version of the 1010G forwarder is available for logging on soft terrain. The distance between the front and rear wheel hubs in the rear bogie is 390 mm longer than in the standard model. The power train and turning radius are the same as with the standard portal bogie-equipped machine. The long bogie brings stability when navigating over obstacles. The lower ground pressure of the rear frame makes the machine an excellent choice for logging in soft terrain and enables bigger loads with the same ground pressure. .

Control systems and automation

The TimberMatic control system and user interface on G-Series forwarders have been further developed and improved to maintain the forest machine’s operational reliability. The TimberMatic features a configurable user interface, cruise control and inclination display. The new software version enables Remote Display Access (RDA) via the Internet (either MTG or other modem). RDA enables faster troubleshooting by servicing people and thus improves the machine’s uptime.

Forwarders have three modules: for the cabin, the front frame and the rear frame. TimberMatic’s troubleshooting diagnostics are more detailed and illustrative. The CAN bus increases reliability of the electrical system: simple, fewer connections, a dedicated bus for the engine and the base machine.

TimberMatic Maps is standard in all new John Deere forest machines. Based on the real time data from Maps to TimberManager, distributed through a cloud service, the contractor can follow up forest machine’s production and remaining work on the site and plan the operations further.

FT4-engine

John Deere Final Tier 4 engines meet the required emissions regulations while also bringing more power and torque. The John Deere 4045 PowerTech Plus, 4,5 liter 4-cylinder engine’s output is 131 kW. The engine is also Stage V-ready.

Especially the low rpm ranges have much torque. The John Deere FT4 engine has the most torque in its class and a wide rpm range. The engine’s rpm remain steady during big and rapid changes in the load. The better coupling of the powerful diesel engine with the power train results in improved tractive force and excellent manoeuvrability in the forest. The FT4 engine and the entire fuel line can use 20% biodiesel.